Application:

We have both rotating type and non-rotating type Casing scraper,which is kind of cleaning tools and cementing tool used to clean thecement, mud, embedded bullets, rust, mill scale, paraffin, perforation burrs and other substances from the inside walls of casing. Maintaining a clean casing ID is important to the operation of all tools used in drilling the well. Adhesive materials on casing walls will frequently cause these tools to become difficult to operation.

To scrape and clean the casing, simply pass the scraper through either with or without rotation. To check a perforated section for smoothness, run the scraper through the section without rotating. If the weight indicator does not show any irregularities the casing has been cleaned.

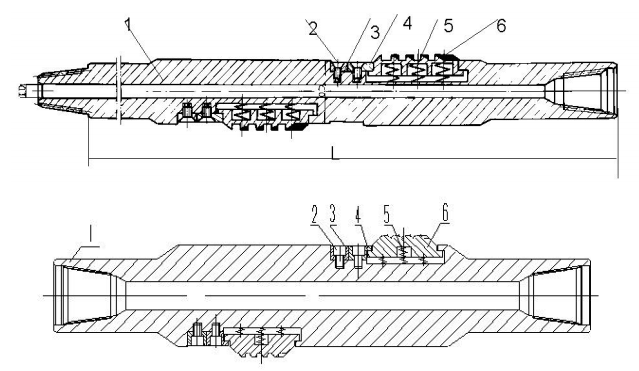

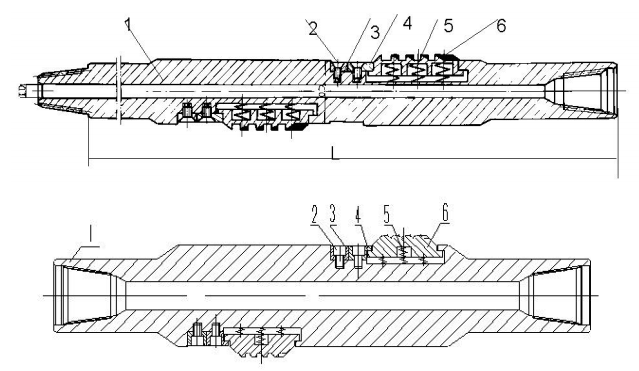

Structure & Principle

Every parts of the casing scraper are made of high quality alloy steel, and fully heat treated. The scraper blades fit into machined recesses and are securely held by a dovetail keeper and spacer. There is left hand helical grooves on the surface of casing scraper, and the edge is high hardness materials for maximum service. There are sufficient blades in the body to completely scrape the casing surface without rotating the tool.

The standard connection of the casing scraper is API REG box and pin. This allows the scraper to be installed in the drilling string between the bit and the bit sub. The bit works under the casing scraper, and has a function of guiding, and also prevents from jamming.

How to order?

1. Casing weight or casing ID shall be given.

2. Size & Connection thread shall be given.